Why are my tiles breaking up or screed breaking up in an tiled floor with underfloor heating? How can I as a tiler avoid underfloor heating failures? What is the best way to tile a floor with underfloor heating? These are all questions that need to be answered.

When planning this blog the top 2 problems that stood out when using underfloor heating were:

- The screed breaking up before or after the tile installation leading to a failed floor and cracked tiles.

- The underfloor heating not working properly following installation of tiles.

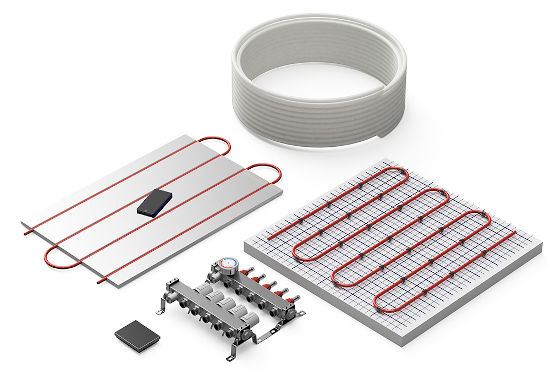

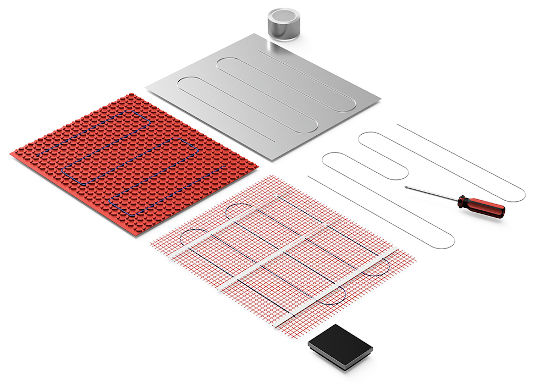

First of all there is 2 different types of underfloor heating systems:

1. Water Pipe System.

2. Electric System.

So why should the screed break up?

| Top Reasons the Screed breaks up. | Solutions |

Screed not properly installed. | Firstly, correctly installing screed with a steel reinforcement will minimize the risks. Secondly, using a decoupling membrane in all instances will further reduce the risk of breakages and any movement of the screed following installation will minimize tile breakages. |

Turning the underfloor heating system on too fast. - This cracks the screed, putting the screed under too much tension. | Turn the underfloor heating on gently, it shouldn't be turned on before you have allowed the screed to cure which takes 28 days following installation. Once you turn the temperature on the underfloor heating system up increase this by 5C a day. |

Turning on the underfloor heating system before 28 days of the screed curing. | Need to let the screed cure for 28 days, otherwise the screed is weakened and will crack later. |

Turning the underfloor heating temperature to more than 22C at any point over heats the tiles and screed, cracking the floor into tiny little bits, completely damaging the floor. | Make sure the water temperature is controlled and can't go over the recommended temperature. |

The underfloor heating was not turned on prior to tiling the floor | Make sure you lay the floor with the underfloor heating on. (Heating on

low)

|

Not having the correct movement bay size. (This differs depending on whether you have underfloor heating or not. Also depending on what screed you are using. eg. sand and cement or anhydrite screed) | The recommended bay size with underfloor heating maximum screed (sand and cement) Bay Size should be 40m2. This is the maximum to have a controlled amount of expansion and contraction. When dividing the room into movement bays, you need to ensure you line up the tile joints to avoid breakages. The movement joints need to be planned in the early stages of the developments so each layer can be installed correctly. |

Differing floor temperatures in different rooms. If each room has a different temperature, eg warmer in the kitchen and cooler in a dining room. Movement joints become critical, the joints between the 2 rooms will keep moving and the force of it can crack tiles. | Make sure you install a proper movement joint in the door way between the 2 doors. |

Cracks where the floor area narrows. - As the floor contracts this is a pressure point. | You should install crack inducers in the floor where the floor narrows. If possible planning these with the movement bays. By introducing controlled places for movement joints you avoid breakages in places you don't want them. Also ensure you have a decoupling membrane, with both crack movement joints and decoupling membrane you can reduce the breakage risk. |

Top Reasons An Underfloor Heating System isn't working properly. | Solutions |

People don’t think through where they are going to fix things into the floor, eg. Toilet pan, bath panel, pivot hinge and go through a wire/pipe. | Think ahead. Plan in where any future trades will need to fix through the floor. |

Cavities left when using a notched trowel over underfloor heating, if there is any cavities around the wire, the electric system will overheat and burn out system. (This is specifically for the electric underfloor heating system) | The adhesive needs to be more runny than usual so it flows completely round the wire leaving no cavities. |

Wire nicked/pipe scratched, this can damage the underfloor heating and you may not realise until after finishing tiling. | Test the underfloor heating prior to tiling, write down the OHMS and after you have finished tiling you do the same again and they should be identical. Double check it and record it and that way you can prove you have done no damage once you hand over to the client. |

2 pieces of electrical wire matting overlapping each other. the wire mats are not allowed to overlap as this over heats the system causing it to burn out. This can happen if you have ordered too much matting for an area and you try to squash it up. | Order the mat slightly smaller than the area requires so you don't have excess. Thinking especially about areas where it won't be needed, eg. kitchen island units, toilet pan. You want the surrounding area warm but not where you need to screw into the ground. And a further tip make sure you have it marked out for where you need to screw, making it easier for the next trade to complete. |

Warm and Cold spots - due to there being gaps in the system | Make sure you order enough to fill areas where you will be needing the underfloor heating. Getting it right is important you can either have too much or not having enough also means not a consistent heat. |

Water Pipe Underfloor Heating System:

Benefits:

- A stable temperature - because both the screed and tile are heated it takes a while to heat up and equally doesn't cool down fast, this makes it an efficient heating system.

- Once your feet are warm, you feel warm, so you can have the room temperature a lot cooler. Breathing cool air is more healthy and you don't need to have central heating on at the same time.

- More energy efficient way of heating.

Drawbacks:

- More complex system to install. Movement joints, appliance/furniture positions and tile positions need to be planned at an earlier stage.

Electrical Underfloor Heating System:

Benefits:

- Heats up quickly as you only heat the tile, and installation needs putting in between the system and screed.

Drawbacks:

- Requires constant electricity making it less economical without a time clock.

- With a time clock it might not be on at the right times so it's more inconvenient.

In summary, planning ahead and thinking about underfloor heating at the design stage will ensure an underfloor heating success and a floor for life. Get the substrate right, plan in your fixtures and follow the correct timings and you will get the correct finish you need.

If you have got any queries or this doesn't answer your question, please contact us and we will help you if we can!

What are the top underfloor heating problems with tiles?